Design and Build Drills

Point to Point Directional Drilling offers its services related on the design and formation of drills. Along their competent professionals, they create a contour map that is generated for an oil, gas, and water reservoir underneath the earth’s field. In this map, the fault line is seen between the contour lies.

With their designs and survey tools, they are able to arrive at well-built drills. The advanced technology helps them to arrive at the mechanical and technical innovations along with hydraulic engineering. As a result, a more efficient well is achieved.

The design of water wells relies on the terrain. The terrain usually consists of bedrock of granite which needs a strong drill with thousands of torque. An aquifer which is not made deeper may require lighter drill. A powerful drill that is faster and more efficient in drilling is used in the ground. On the other hand, the lighter drill is made more compact with less maintenance.

The choice of the right rig is also included in the design of drills. Depending on the depth of the well, the rig used is less or more powerful. Mechanical rigs are an essential part of the design that fit on the purpose of drilling wells. They are actually operated by the diesel engines.

As part of the design in building wells, they look for the perfect place to find them. The water source is ensured to be found in the area such as the body of water and stream. They also require for one-hundred feet water source in order that the water can consider the ground as natural filler. The well is one-hundred feet from the source of contamination such as toilet, dump and animal area.

Digging the well is another step included in the design. The well is dug out for five feet diagonally in the spherical shape. Digging is quite dangerous that the company and its professionals are ready to provide the service of building drills. The digging comes along with pick and shovel and is continued until the water is caught for about six feet deep.

The underneath part of the well is covered with the use of five to six inches of little rocks. These rocks act as filters in keeping insects and wildlife away from entering the well. The brick is reinforced with the borders of the well. Then, the process of building well is started from the bottom. The brick and mortar are only used for five or six layers. The edges are reinforced with the use of bricks.

The design continues on top of the brick and mortar; the top must be covered with concrete slab or stone. The hole is left on the pump for the well to be used readily.

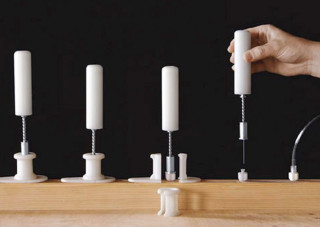

More so, the design they create on a drill withstands depths, geological barriers and extreme pressures. The precision further allows for optimum well drilling. The drill is made from the strongest and hardest material that bores its method on any obstacle that may be present.

Point to Point Directional Drilling has its multiple options in building drills along multiple designs. They are considered important for versatile and effective well-drilled wells. They are an excellent way in creating wells in the present landscape- either for extracting oil or creating water wells. Solutions are also a part of delivering the drilling need of clients!